A

Powder Coating Machine is a sophisticated piece of equipment meticulously designed to apply a dry powder coating onto diverse surfaces. It primarily comprises three key components: a powder hopper, a spray gun, and an electrostatic charging system. The powder hopper serves as the storage unit for the powder coating material. The powder - feeding mechanism, which can operate either on a gravity - fed principle or through pneumatic means, efficiently transfers the powder to the spray gun. The spray gun, integrated with an electrostatic generator, imparts an electrostatic charge to the powder as it is being sprayed. This charged powder is then attracted towards the grounded workpiece, resulting in the formation of a uniform and firmly adherent coating.

Powder Coating Machines find extensive application across a multitude of industries. In the automotive industry, they are employed to coat car bodies, bestowing a smooth, corrosion - resistant finish that not only enhances the vehicle's aesthetic appeal but also extends its lifespan. In the furniture manufacturing sector, metal furniture parts such as frames and legs are coated to enhance both their visual allure and durability. In the electronics industry, the enclosures of electronic devices are powder - coated to safeguard against dust and moisture, ensuring the optimal performance and longevity of the devices.

The price of

Powder Coating Machines varies substantially depending on their features and capabilities. An entry - level, basic model suitable for small - scale DIY projects or hobbyists can be acquired for approximately $150 - $300. These machines typically feature a simple structure and offer basic functionality. Mid - range machines, equipped with features like adjustable powder flow and enhanced electrostatic control, generally cost between $800 - $2000. High - end, industrial - grade Powder Coating Machines, furnished with advanced powder - reclaim systems, precise temperature control, and high - speed spraying capabilities, can cost upwards of $4000.

Prior to operating the Powder Coating Machine, it is imperative to ensure that the workpiece is thoroughly clean, free from any dirt, grease, or rust. Connect the machine to a stable power source and verify that it is properly grounded to prevent electrical hazards. Adjust the powder - flow rate in accordance with the size and shape of the workpiece. Larger workpieces may necessitate a higher powder - flow rate to achieve an even coating. Set the electrostatic voltage according to the type of powder being used. When spraying, hold the gun perpendicular to the workpiece and move it at a consistent speed. Maintain a distance of approximately 15 - 20 cm between the gun and the workpiece to obtain the best possible results.

When choosing a

Powder Coating Machine, the first factor to consider is your production volume. For high - volume production lines, an industrial - grade, fully automatic machine equipped with large - capacity powder - reclaim systems and high - speed spraying capabilities is indispensable. For small - scale production or occasional use, a manual or semi - automatic machine proves to be more cost - effective. Additionally, take into account the types of materials you will be coating, as different materials may demand different electrostatic settings and powder - flow rates. Your budget is another crucial determinant. Strike a balance between your requirements and the cost to identify the most suitable machine.

Safety should always be the utmost priority when using a

Powder Coating Machine. Wear appropriate personal protective equipment (PPE), including a dust mask to prevent the inhalation of powder particles, safety goggles to protect your eyes from potential splashes or flying debris, and gloves to safeguard your hands. Operate in a well - ventilated area to avoid the accumulation of powder in the air, which can pose a significant fire or explosion hazard. Regularly inspect the machine's electrical components and wiring to prevent electrical accidents.

The design of a Powder Coating Machine is highly rational. The electrostatic charging system not only ensures efficient powder adhesion, thereby enhancing the quality of the coating, but also minimizes powder waste, making the process more cost - effective. The adjustable powder - flow and spray - pattern settings enable customization according to the specific requirements of different workpieces. The use of high - quality, durable materials in the construction of the machine ensures its long - term reliability and performance, making it a sound investment in the long run.

Q: What should I do if the powder coating has a mottled appearance?

A: First, meticulously check the powder - flow rate; it might be inconsistent. Also, ensure that the electrostatic charge is evenly distributed across the powder. Thoroughly clean the spray gun and the powder - feeding system to eliminate any potential blockages.

Q: Can I use a Powder Coating Machine in a humid environment?

A: It is not advisable. High humidity can detrimentally affect the powder's flowability and the adhesion of the coating. If you must work in a humid environment, consider employing a dehumidifier or a powder - drying device.

Q: How do I clean the electrostatic charging system?

A: First, disconnect the power supply to avoid any electrical mishaps. Then, use a soft, dry brush to gently remove any powder residue. Refrain from using water or liquid cleaners, as they may damage the sensitive electrical components.

Q: Can I modify the powder - feeding mechanism of my Powder Coating Machine?

A: Modifying the powder - feeding mechanism is not recommended unless you possess professional knowledge. Incorrect modifications may lead to the malfunctioning of the machine. If you have specific requirements, consult the manufacturer or a professional technician.

Q: What if the powder doesn't spray out evenly?

A: Check the powder hopper for any clogs that could impede the flow of powder. Also, ensure that the air pressure (if it's a pneumatic powder - feeding system) is stable. Clean or replace the spray gun nozzle if it is dirty or damaged.

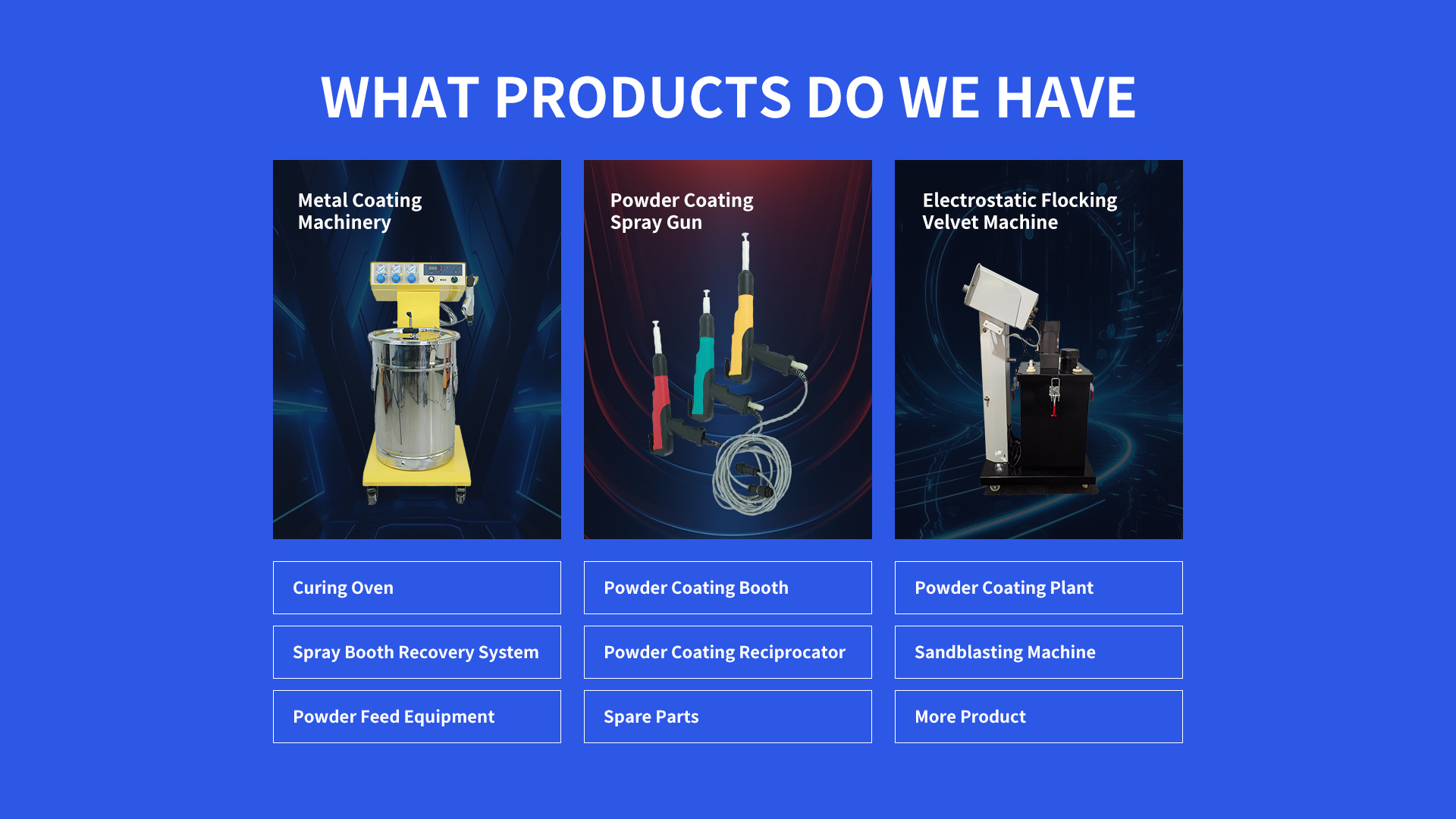

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com